A powder coating line transforms metal surfaces into durable, high-performance products through electrostatic application and thermal curing. This environmentally compliant process offers superior corrosion resistance and efficiency via automated conveyor systems. However, its success hinges entirely on pretreatment—the critical initial stage where contaminants like oils, rust, or residues are removed via cleaning, chemical conversion, and rinsing.

Defects in powder coating pretreatment—such as residual oils, incomplete phosphating, or water spots—directly cause coating failures. These include fish eyes, poor adhesion, peeling, and premature corrosion. This guide provides actionable steps to identify and resolve such defects, ensuring flawless finishes and operational efficiency in your powder coating line.

I. Pretreatment Methods in Powder Coating Line: Spray vs. Dip Tank System

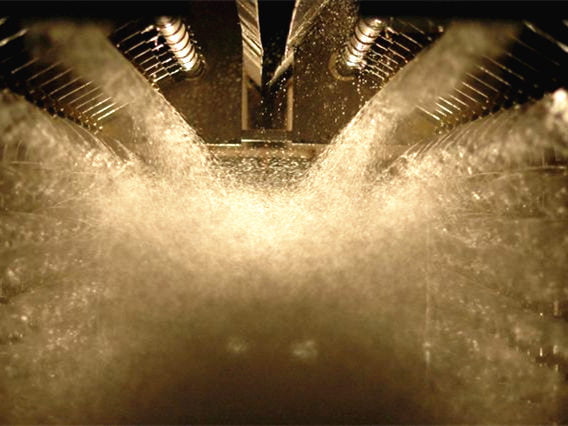

Spray Pretreatment: Speed and Surface Coverage

Spray pretreatment leverages high-pressure nozzles to propel chemical solutions onto conveyor-mounted parts. This method excels in high-volume production lines, where speed is critical. Its targeted jets efficiently remove oils, particulates, and light rust from exposed surfaces—ideal for flat or simple-geometry components like sheet metal cabinets or appliance panels. However, shadow areas may evade full coverage due to line-of-sight limitations. Nozzle clogging from debris or mineral buildup also poses frequent maintenance challenges, risking uneven cleaning and chemical waste.

Dip Tank Pretreatment: Precision for Complex Parts

Dip tank pretreatment immerses parts fully in sequential chemical baths for thorough, 360° contaminant removal. This immersion approach is indispensable for intricate components with cavities or internal channels—such as automotive frames or bicycle handlebars—where spray jets cannot penetrate. The prolonged bath contact ensures uniform conversion coatings, enhancing corrosion resistance. Yet, drawbacks include chemical carryover between tanks, sludge accumulation degrading bath efficacy, and slower processing speeds.

II. Common Powder Coating Pretreatment Defects & Causes

- Oil/Grease Contamination Residue

Fish eyes or pinholes on cured surfaces signal oil/grease contamination, primarily caused by depleted degreaser baths, inadequate rinsing allowing mineral redeposit, or carryover oils from conveyors. This residue breaks surface tension, triggering adhesion failure and hidden corrosion.

- Incomplete/Weak Conversion Coating

Patchy phosphate/chromate layers and low gloss result from chemical imbalances, short process times leaving complex areas uncoated, or substrate incompatibility. Weak conversion coatings slash corrosion resistance by 50% and cause peeling.

- Water Spots & Flash Rust

White mineral deposits or orange rust blooms stem from residual moisture, impure rinse water, or delayed processing. These defects seed micro-corrosion and disrupt powder flow during curing.

- Surface Inconsistencies

Visible sanding marks or localized peeling arise from abrasive blasting errors, over/under-etching in alkaline baths, or sludge-laden dip tanks compromising adhesion. Inconsistent textures weaken mechanical bonding.

III. Step-by-Step Powder Coating Pretreatment Inspection Protocol

1. Chemical Bath Validation

Temperature & Pressure:

- Manually verify bath temperatures with calibrated thermometers (±2°C tolerance).

- Spray systems: Maintain nozzle pressure at 15–25 psi; dips ensure agitation consistency.

Concentration & Contamination:

- Test pH and chemical levels (e.g., zinc phosphate: 15–25 points; degreaser alkalinity: 20–30 points).

- Replace baths if oil exceeds 50 ppm or sludge volume >10%.

2. Water & Substrate Check

Rinse Water:

- Measure conductivity: >50 μS/cm indicates dissolved solids (e.g., chlorides).

- Maintain final rinse at 40–50°C to prevent flash rust.

Substrate Compatibility:

- Confirm lubricants are silicone-free.

- Perform water-break tests: uniform sheeting confirms cleanliness; beading indicates oil residue.

3. Equipment & Process Audit

- Spray Systems: Inspect nozzles for clogs (flow drop >15%) or misalignment.

- Dip Tanks: Verify agitation pump function to prevent stratification.

- Process Adherence: Confirm dip time (90–120 sec) and spray coverage (≥95%).

4. Conveyor System Check

- Speed Consistency: Measure with a tachometer; deviations >±0.2 m/min from setpoints (e.g., 1.6 m/min) disrupt dwell times.

- Transfer Zones: Ensure drainage time (5–10 sec) and part racking tilt (15°–30°) to prevent solution pooling.

Conclusion

Precision in powder coating pretreatment is the cornerstone of coating durability and performance. As demonstrated across spray and dip tank systems, deviations in chemical concentration, temperature tolerance, or process timing directly trigger defects like poor adhesion, flash rust, or oil residue—accounting for over 70% of coating failures. Rigorous control of these parameters, coupled with systematic inspections, mitigates risks by ensuring uniform conversion coatings and eliminating contamination vectors. In the powder coating line, the integration of quantifiable standards transforms pretreatment from an art to a science.