For decades, factories grappled with the challenges of manual powder coating – inconsistent finishes, high labor costs and turnover, significant material waste, and safety concerns for operators. Today, a smarter solution is driving a fundamental shift: the powder coating robot. These advanced robotic systems are no longer a futuristic concept but a strategic necessity for competitive manufacturers seeking superior quality, dramatic cost savings, enhanced productivity, and safer operations. Factories increasingly choose powder coating robots because they deliver unparalleled consistency, efficiency, and reliability, transforming the finishing process from a bottleneck into a competitive advantage.

How Powder Coating Robots Elevate Finish Quality

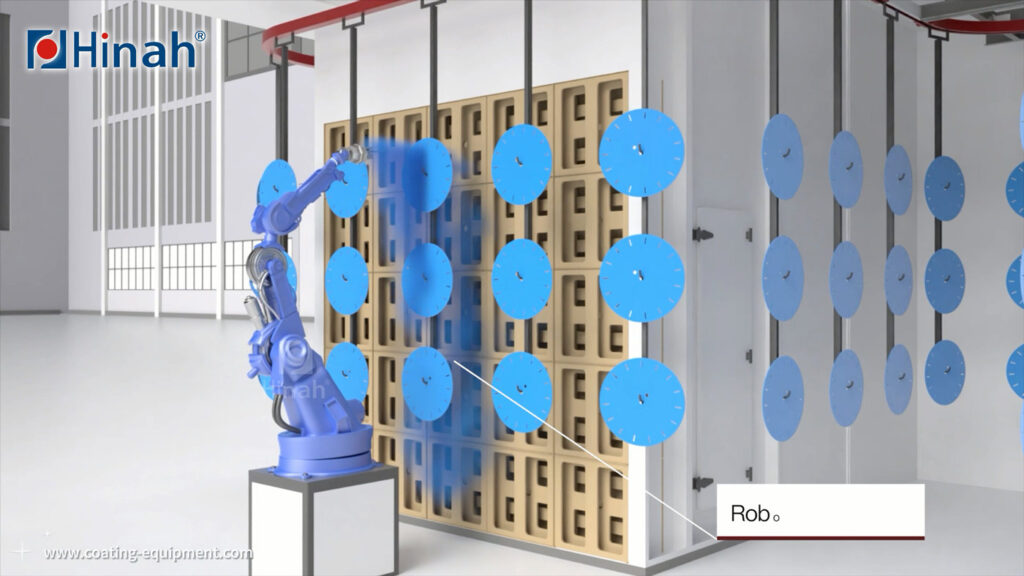

Human operators, no matter how skilled, inherently introduce variability into the powder coating process. Fatigue, slight movements, and environmental factors can lead to inconsistent spray patterns, resulting in uneven film thickness, over-spray, under-spray, and common defects like runs, sags, or orange peel. This is where the powder coating robot becomes indispensable. Programmed with pinpoint accuracy, these robotic systems execute identical, optimized spray paths pass after pass. They maintain perfect gun-to-part distance and angle, ensuring consistent powder coating application over even the most complex geometries and hard-to-reach areas. This robotic coating precision guarantees uniform thickness and optimal electrostatic charge transfer across the entire part surface, significantly enhancing powder adhesion. The result? Repeatable powder application delivers a flawless, high-quality finish batch after batch, drastically reducing rework and scrap rates while elevating the perceived value and durability of the final product. For factories demanding perfection and brand-defining quality, the powder coating robot is the ultimate solution.

The Speed of Automatic Powder Coating

In fast-paced manufacturing environments, production bottlenecks cost revenue. Powder coating robots eliminate finishing line slowdowns by operating at relentless, optimized speeds impossible for human operators. Unlike manual spraying constrained by fatigue, breaks, and variable pace, a high-speed powder coating robot maintains peak performance 24/7. Programmed paths minimize non-spray movement, while consistent gun triggering and traversal velocity ensure faster powder coating processes – often completing cycles 30%+ quicker than manual methods. Crucially, these systems integrate seamlessly with conveyors and material handling automation, creating continuous flow. This synchronization prevents queues, maximizes booth utilization, and allows robotic painting throughput to scale with demand. Quick reprogramming enables near-instant changeovers between part types or colors, slashing downtime. The result? Automated coating line productivity soars, transforming powder coating from a bottleneck into a powerhouse that keeps pace with – and even accelerates – your entire production rhythm.

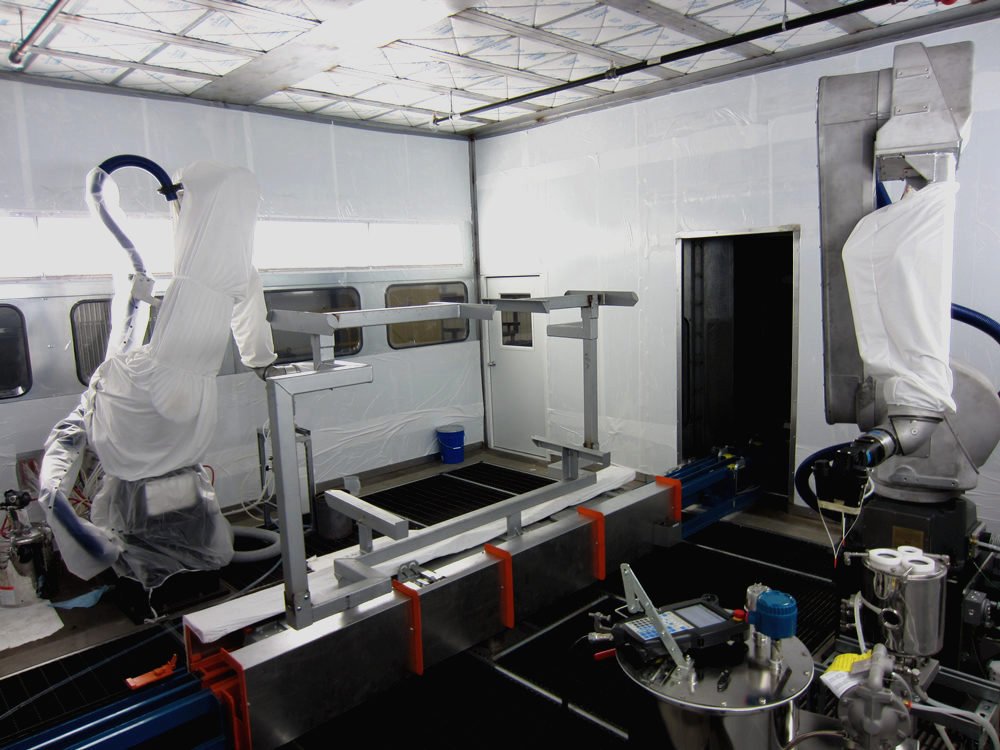

Powder Coating Robot Safety & Sustainability

Manual powder coating operations expose personnel to significant health risks: airborne powder particulates, chemical fumes, and repetitive stress injuries from spraying complex parts. Powder coating robots eliminate these hazards by removing operators from the spray environment entirely. By automating the application process, factories drastically reduce operator exposure to respiratory irritants and ergonomic strains, safeguarding worker wellbeing. The precision of robotic coating systems further enhances safe powder coating automation by minimizing overspray drift and containing contaminants within the booth – creating inherently healthier factory floors.

Beyond human safety, powder coating robots deliver powerful environmental advantages. Their pinpoint application accuracy achieves >95% transfer efficiency – dramatically slashing raw material consumption compared to manual methods. Advanced recovery systems capture and reuse virtually all oversprayed powder, reducing waste disposal volumes by 40-60%. This closed-loop process supports eco-friendly powder coating initiatives and helps manufacturers meet sustainability targets. The result is cleaner production that aligns with ESG goals while reducing regulatory risks – transforming compliance from a cost into competitive advantage.

Conclusion

Factories no longer choose powder coating robots merely for innovation – they adopt them as strategic necessities. As demonstrated, these systems deliver transformative advantages: unmatched finish quality through robotic precision, accelerated production speeds that eliminate bottlenecks, and inherently safer, sustainable operations aligning with modern compliance standards. The combined impact – elevated product consistency, dramatic cost savings, and future-proofed facilities – makes automation non-negotiable for competitive manufacturing.

The shift isn’t coming; it’s here. By integrating robotic powder coating systems, forward-thinking factories transform finishing from a variable cost center into a scalable competitive edge. Ready to revolutionize your production?