Top 3 Benefits of Using a Modern Powder Recovery System

No one likes to see valuable powder go to waste, and yet in many powder coating lines, overspray is simply treated as a loss. That’s where a modern powder recovery system changes the game. Instead of watching material (and money) disappear into the air, companies are finding smarter ways to capture it, reuse it, and […]

What Really Happens Inside the Automated Paint Line

When looking at a perfectly coated product—smooth, flawless, and durable—it’s easy to forget the journey it has taken to get there. Behind the shine and color lies a highly orchestrated process that most people never see. An automated paint line isn’t just a row of machines working in sync; it’s a living system where every […]

The Hidden Energy Costs of Powder Coating Conveyor

When people think about the energy demands of a powder coating line, the ovens and spray booths usually take center stage. Yet hidden in plain sight, the powder coating conveyor quietly consumes power every hour it runs. Because it is often seen as just a “moving tool,” its energy impact can be underestimated or even […]

What Installation Challenges Are Common in Powder Dip Coating Line?

When a new powder dip coating line is delivered, the excitement often comes with a fair share of pressure. Installation isn’t just about putting machines in place—it’s about making sure every component works together as a system. A small mistake during setup can lead to uneven coatings, wasted energy, or unexpected downtime later on. That’s […]

Automatic Powder Coating Line: What Causes Poor Powder Adhesion

Every automatic powder coating line is built with one clear goal: to deliver a smooth, durable, and beautiful finish. Yet nothing is more frustrating than seeing powder scatter in the booth or peel away too easily from the surface. Poor adhesion doesn’t just spoil the look — it means wasted material, higher costs, and disappointed […]

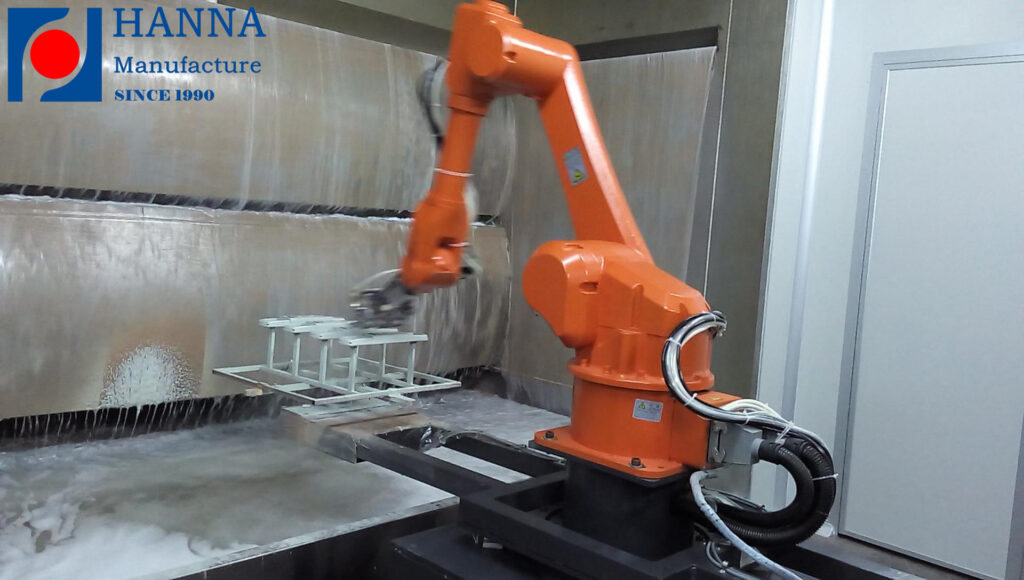

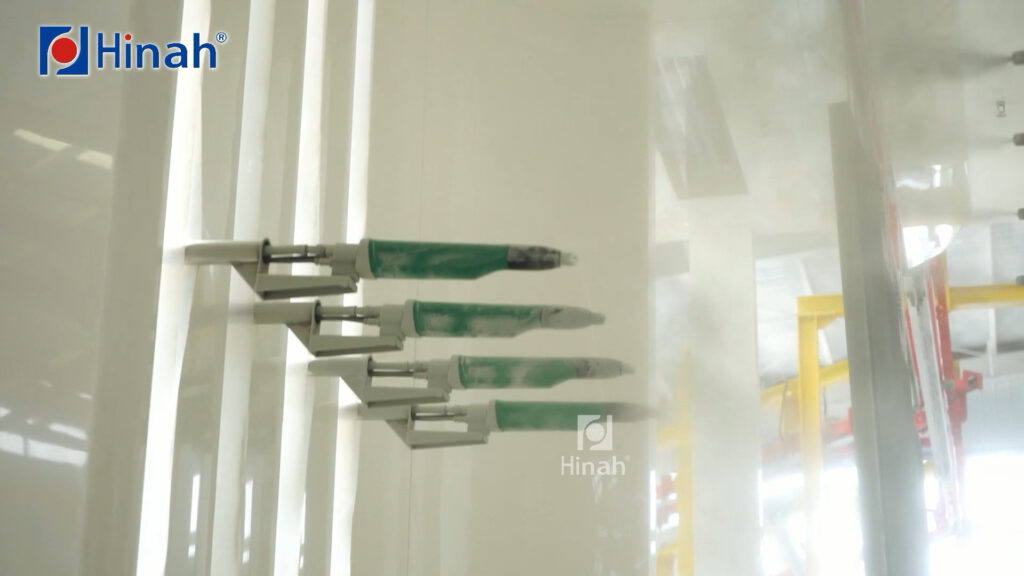

Why Automatic Painting Line with Robotic Arms Reduce Paint Waste

Paint waste is more than a cost—it’s a constant challenge on the production floor. Small inconsistencies in manual spraying can lead to overspray, rework, and frustration. The automatic painting line with robotic arms changes that. With precise, repeatable movements, robotic arms ensure paint goes exactly where it’s needed, reducing waste and delivering a consistently high-quality […]

The Critical Role of Airflow in Automated Paint Line Operations

In an automated paint line, airflow is like the invisible hand guiding every droplet of paint to its perfect place. It’s the quiet partner in the background, making sure colors coat evenly, surfaces stay clean, and every finish looks as good as it should. When airflow is balanced and well-managed, the whole operation runs smoother—paint […]

How to Reduce Wastewater Carryover in a Powder Coating Line?

In every powder coating line, water isn’t just a resource — it’s part of the rhythm of production. But too often, we see it quietly slipping away through unnecessary carryover, increasing costs and putting pressure on wastewater systems. When spraying aluminum parts using electrostatic coating, even small inefficiencies can lead to big waste. The good […]

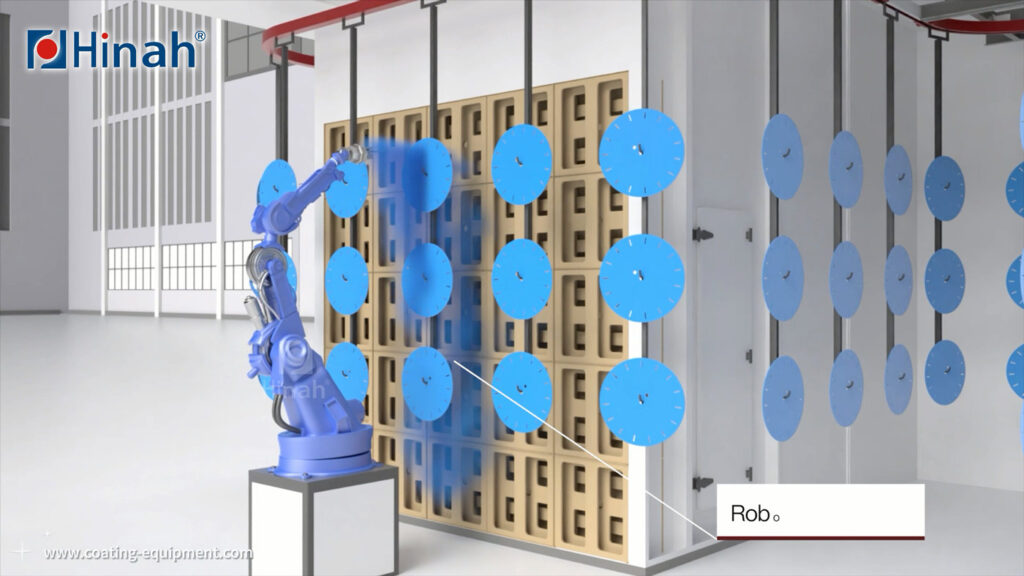

Why Factories Choose Powder Coating Robot

For decades, factories grappled with the challenges of manual powder coating – inconsistent finishes, high labor costs and turnover, significant material waste, and safety concerns for operators. Today, a smarter solution is driving a fundamental shift: the powder coating robot. These advanced robotic systems are no longer a futuristic concept but a strategic necessity for […]

Maximizing Powder Coating Line Output: Why Voltage Matters

In the competitive world of surface finishing, powder coating line operators constantly seek to maximize throughput while minimizing waste. Yet many overlook a critical lever hidden in plain sight: electrostatic voltage. Far more than a technical setting, voltage directly dictates your line’s efficiency, quality, and ultimately – your bottom line. Why does voltage hold such […]