The push for greater productivity and flawless finishes is transforming powder coating. Integrating a powder coating robot into your powder coating line offers a powerful solution, moving beyond the constraints of manual spraying or reciprocators.

These advanced systems deliver significant advantages where it matters most: maximizing equipment uptime, ensuring consistent coating quality, and reducing waste. They represent a strategic upgrade for manufacturers seeking a competitive edge.

This article explores the key benefits of powder coating robots and how they enhance the performance of your coating operation.

Advantage 1: Unmatched Line Utilization of Powder Coating Robot

Traditional automated solutions like reciprocators struggle with significant operational limitations. Their rigid mechanics and frequent repositioning requirements lead to substantial idle time, inherently capping the overall productivity of your powder coating line. This downtime directly restricts throughput and inflates operational costs.

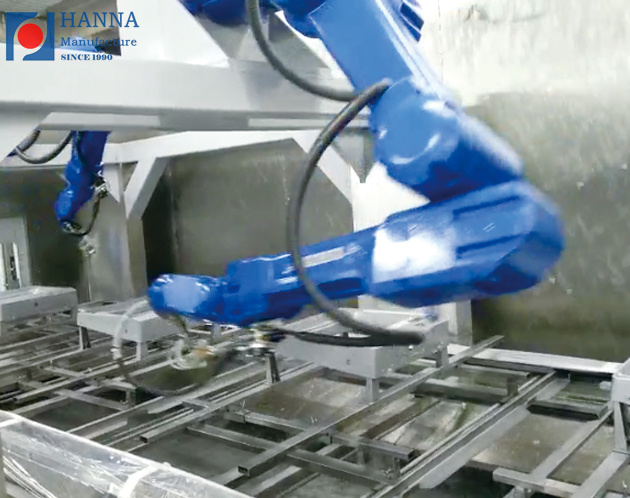

In stark contrast, powder coating robots deliver near-continuous operation. Their advanced articulation and programmable workflows minimize non-productive movements, keeping the application process active far longer. This translates to dramatically higher powder coating line utilization. The result? Your coating cell achieves significantly greater throughput capacity without expanding the physical footprint, while simultaneously reducing powder waste generated during idle periods. This efficiency fundamentally transforms your production potential.

Advantage 2: Enhanced Application Versatility & Coverage

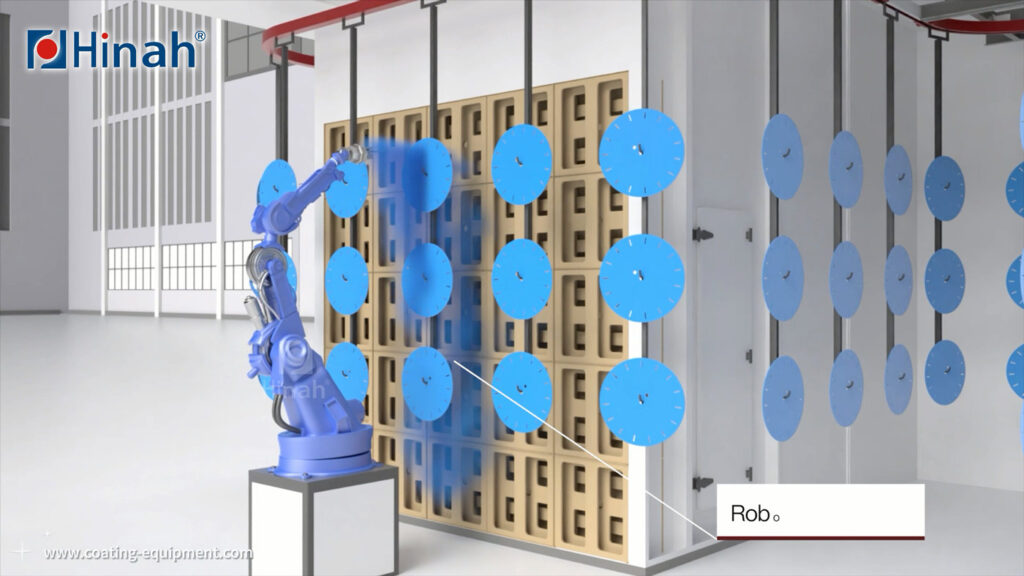

Traditional coating methods, including fixed automation like reciprocators, often struggle with complex part geometries. Coating intricate internal surfaces, deep recesses, or parts with challenging angles consistently can be difficult or impossible, limiting the range of products your powder coating line can handle effectively.

Powder coating robots overcome these limitations entirely. Their advanced multi-axis articulation and precise programmable paths allow them to maneuver coating guns into positions impossible for rigid systems. This enables uniform application on both external surfaces and hard-to-reach internal areas with equal consistency. The result is significantly expanded coverage capabilities – a single robot can expertly coat a vast array of complex shapes and sizes. This inherent flexibility also simplifies handling mixed-production runs, allowing diverse parts to be coated efficiently on the same line without costly retooling. Robots revolutionize what your finishing process can achieve.

Advantage 3: Consistent Quality & Reduced Waste from Powder Coating Robot

Achieving flawless, uniform finishes consistently is a major challenge with manual spraying or fixed automation. Variations in operator technique or the rigid paths of reciprocators often lead to uneven film thickness, inconsistent appearance, and quality issues like orange peel or dry spray – directly impacting product value and customer satisfaction.

Powder coating robot eliminates this variability. Its programmable precision allows it to replicate the exact optimal spray path, speed, and gun orientation for every part, cycle after cycle. This robotic accuracy ensures exceptional coating uniformity, both in film thickness and visual quality, across every workpiece. Crucially, this precision isn’t just about looks; it significantly boosts material utilization. By directing powder precisely onto the target surfaces and minimizing stray overspray, powder coating robots dramatically reduce powder consumption and the associated waste. This efficiency also lessens powder buildup in the booth, reducing cleaning frequency and solvent use, streamlining your entire powder coating line operation.

Advantage 4: The Operational Benefits of Powder Coating Robot

Beyond boosting quality and efficiency, powder coating robots significantly simplify daily operations and reduce long-term maintenance burdens compared to traditional systems. This translates to less downtime and lower total cost of ownership for your powder coating line. Key operational advantages include:

- Effortless Offline Programming: New part programs are created away from the production floor using intuitive simulation software. This eliminates lengthy shutdowns for manual “teaching,” allowing your powder coating line to maintain maximum uptime. Program adjustments and new job setups become rapid tasks, not major disruptions.

- Unmatched Maintenance Accessibility: Powder coating robots are engineered with serviceability in mind. Critical components – such as the applicator, hoses, pumps, and filters – are strategically positioned for easy access. Technicians can perform routine checks, cleaning, and component replacements quickly and safely, minimizing interaction with complex internal mechanisms.

- Modular Design for Rapid Repair: Embracing a plug-and-play philosophy, key subsystems and wear parts feature modular construction. Faulty modules can be swapped out in minutes instead of hours, drastically slashing Mean Time To Repair. Spare modules ensure your robot spends minimal time offline.

The result is a powder coating robot that integrates smoothly, adapts quickly to changing production needs, and stays productive with minimal operational friction. Reduced engineering time, faster changeovers, and swift maintenance keep your powder coating line running consistently at peak performance.