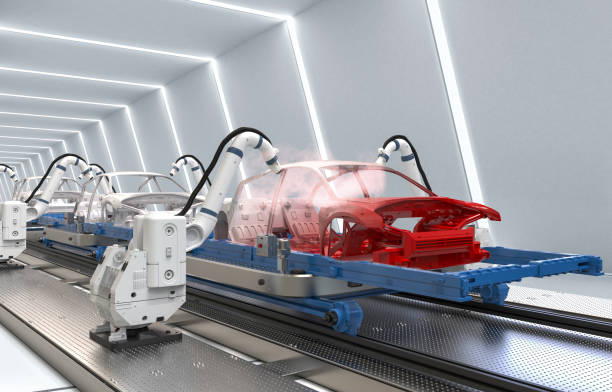

Every car that leaves the production line faces the same invisible enemies—corrosion, sunlight, moisture, and road debris. Over time, these elements slowly attack the vehicle’s surface, dulling its shine and weakening its structure. Protecting the car body isn’t just about aesthetics; it’s about preserving the vehicle’s strength and lifespan. That’s why more are turning to the automated paint line. With its precise control, consistent coating, and dust-free environment, it delivers a level of protection that manual painting simply can’t match. It’s not just automation—it’s a promise of lasting beauty and durability for every car that hits the road.

Consistent Coating Quality Through Automated Paint Line

When it comes to automotive body protection, consistency is everything. Even the smallest variation in coating thickness can lead to weak spots—areas where corrosion starts to creep in, slowly compromising the entire surface. This is where the automated paint line shows its true value.

Every spray, every movement, and every rotation is precisely programmed. The system maintains a steady spray distance and uniform gun speed, ensuring the same perfect layer on every inch of the car body. Corners, edges, and curves—all receive equal attention. Unlike manual painting, there’s no fatigue, no guesswork, and no uneven coverage.

By keeping coating thickness stable, the automated paint line guarantees that the protective layer performs as it should—forming a reliable shield against rust, humidity, and abrasion. The result is not just a flawless appearance, but long-term durability that gives every vehicle a fighting chance against time and the elements.

Automated Paint Line Control Guarantees Durability and Efficiency

Durability doesn’t happen by chance—it’s the result of perfect control at every stage of the coating process. Inside an automated paint line, every parameter matters: air pressure, spray angle, paint flow, oven temperature, and even humidity levels. Together, they decide how strong, smooth, and long-lasting the final layer will be.

Automated systems make this control possible with pinpoint precision. Sensors constantly monitor the environment, adjusting in real time to keep the coating process stable. The curing oven maintains the ideal temperature profile so that paint particles bond firmly to the metal surface, forming a tough and flexible shield. The outcome is a coating that not only looks impeccable but resists chipping, peeling, and fading for years.

At the same time, automation boosts efficiency. Paint usage is optimized, overspray is reduced, and production runs remain consistent from the first car to the thousandth. No interruptions, no wasted material—just a streamlined, repeatable process that saves both time and cost while protecting every vehicle that passes through.

Comprehensive Body Protection with Automatic Painting Technology

A car body isn’t just flat panels—it’s a complex shape of curves, edges, and recesses. Protecting every surface evenly is a challenge that manual spraying often fails to meet. But an automated paint line is built for precision. With programmable robotic arms and controlled spraying angles, it ensures that even the hardest-to-reach corners receive the same level of coverage and protection.

Inside a clean, enclosed spray booth, filtered airflow keeps dust and particles away from the freshly painted surface. This means fewer defects, smoother finishes, and stronger adhesion between each layer of paint. From the roof to the underbody, from the doors to the inner frame, every part of the car leaves the line with a consistent, high-quality protective coat.

This combination of precision, cleanliness, and full-surface coverage is what truly sets the automated paint line apart. It doesn’t just coat the car—it shields it completely, giving each vehicle a uniform armor against corrosion, weathering, and daily wear.