Want to Discuss Your Upcoming Product Line?

Hinah coating will help you get things done.

Email us

Tel (Whatsapp/Wechat)

+86-186 3213 8668

Home » Products » Fully Automatic Liquid Painting Line » Liquid Dipping Line For Flange Profile

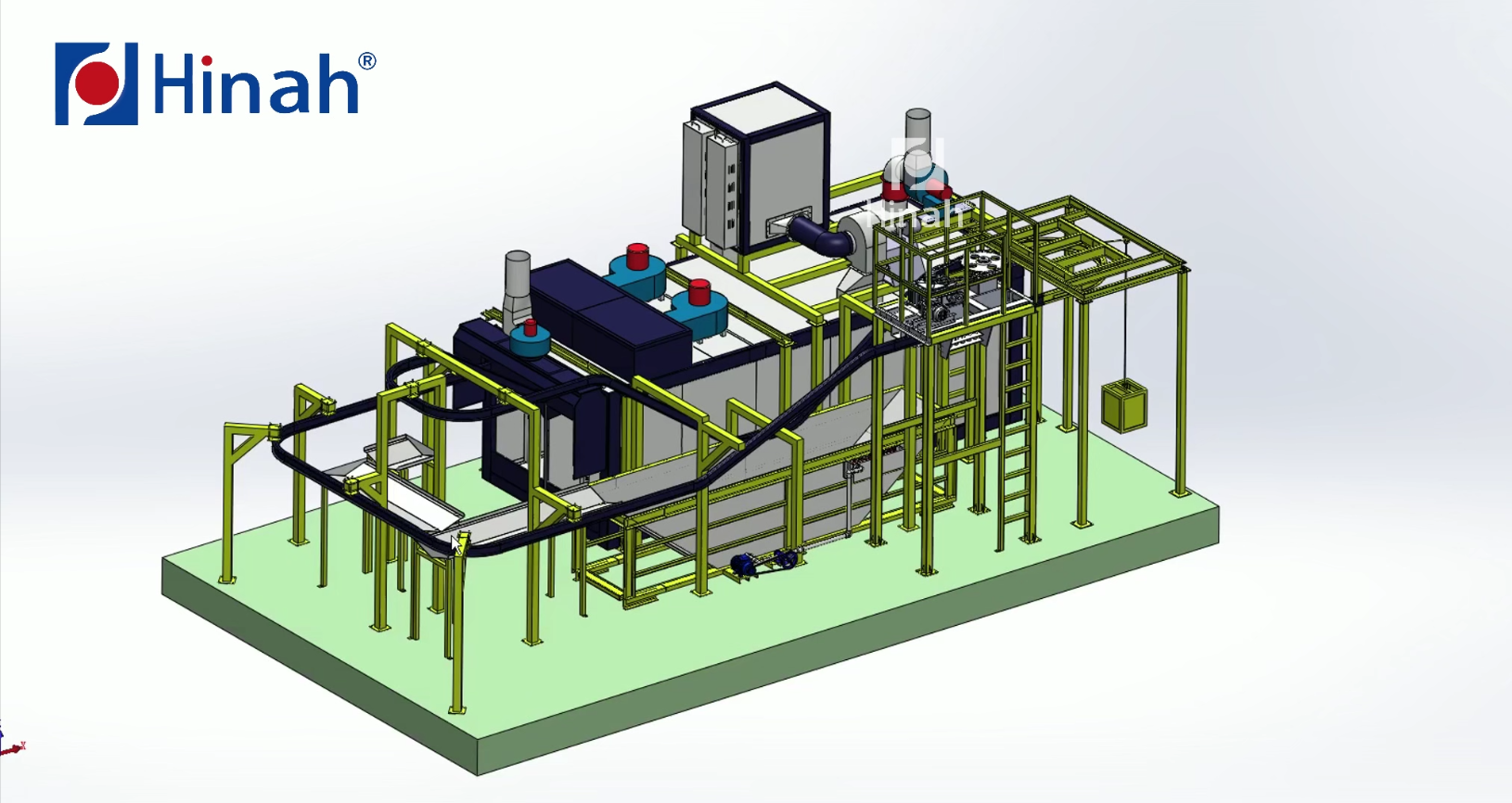

Liquid Dipping Line Project For Flange Profile

Flexible and efficient e-coating system.

Process Flow: Loading– Pre-Treatment –Drying–Liquid Dipping –Curing –Cooling –Unloading

1. Workpiece Name: Flange

2. Maximum Size: L7000*W500*H1700 (Mm)

3. Area Size: 89m*15m

4. Heating Method: Natural Gas

5. Conveying Specifications: Qxg250 Type

6. Conveying Length: 500 Meters

Design and features

We deliver precision-engineered processes, intelligent equipment, and eco-friendly, high-efficiency, superior adhesion powder coating solutions. Utilizing electrostatic adsorption and high-temperature curing technology, our powder coating line creates durable, uniform surface coatings, widely applied in home appliances, automotive, construction, and industrial equipment sectors.

Adjusted at a later stage

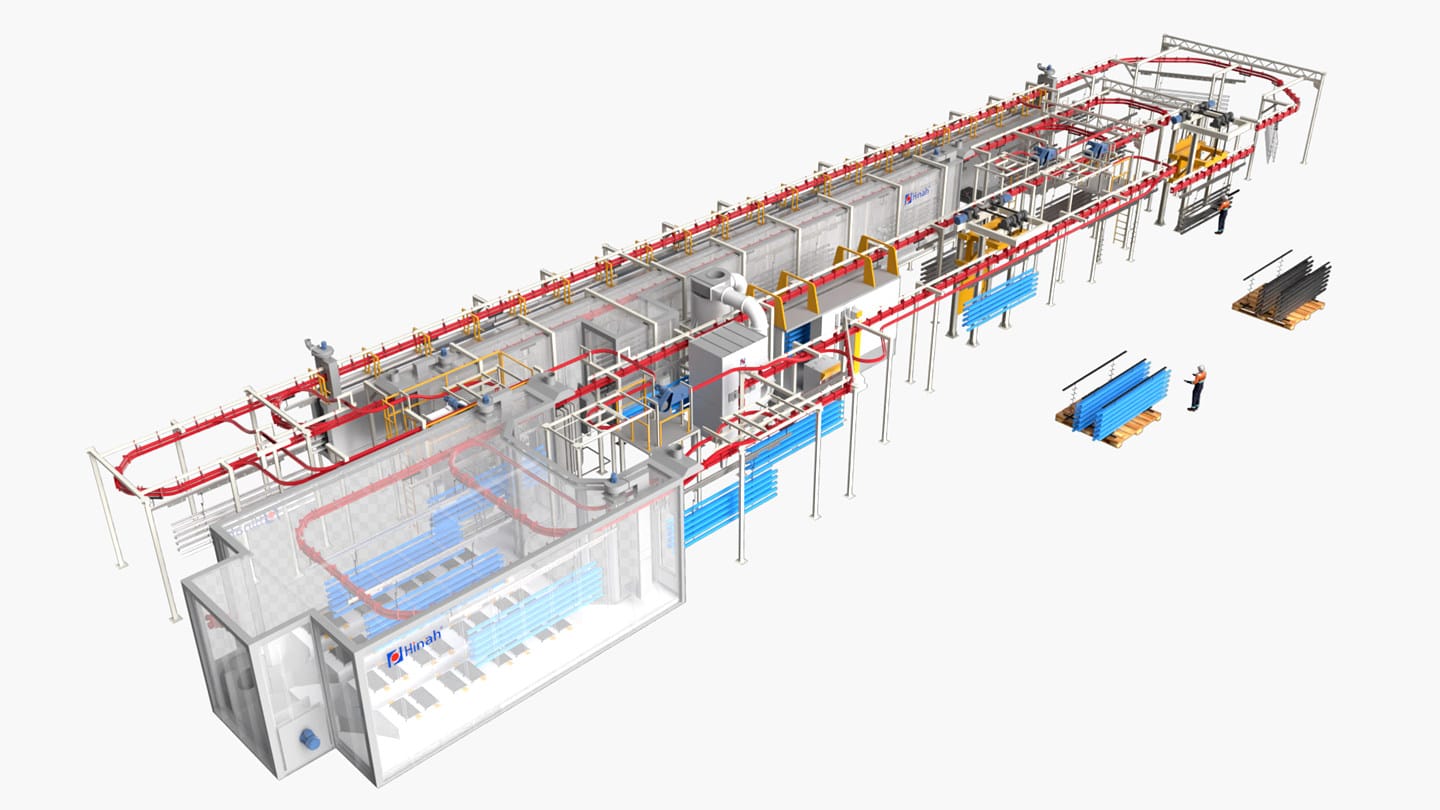

1. This is a typical standard liquid dipping line, generally used for products with complex geometries, porous surfaces, or demanding coating uniformity requirements. It suits high-output scenarios where full coverage and penetration are critical.

2. The line adopts heavy-duty stainless steel chain-plate conveyors as the core workpiece handling system, characterized by chemical corrosion resistance, high load capacity, and minimal maintenance needs with low failure rates.

3. The layout strictly follows wet-dry zone separation: The dipping and draining section (wet zone) is positioned against the workshop wall, while the curing oven (dry zone) is placed externally near the loading/unloading area for centralized management. An enclosed drainage tunnel bridges both zones, preventing solvent interference with curing.

4. The dipping method guarantees 100% coverage on recessed areas and internal cavities, achieving superior adhesion and void-free coating with industry-leading transfer efficiency.

- All Types Of Equipment For Liquid Painting Lines

- Any Size According To Customer's Requirements

- Production Within 45-90 Days

- Delivery And Professional Installation

- 24 Months Warranty And Lifetime Service

Proven

30 years of experience providing proven equipment

Lifetime Service

Maintenance is more important than repair

Maximum Efficiency

Production line capacity fully matches demand without wasting any resources

Contact Us -- Free Design & Order Equipment Calculation

Order Equipment Calculation

In Order To Provide You With The Best Solution, Please Tell Us The Following Information

● Factory Dimensions (length, width, height)

● Work Piece Output (1 day = 8 hours, 1 month = 30 days)

● Material of the workpieces

● Dimensions of work piece

● Weight of the workpieces

● Color Change Demand (Frequency)

We closely communicate with clients to understand their needs and provide tailored solutions. Once the solution fits their requirements, we customize the production of the powder coating line to help them adapt to their specific production environment and coating needs.

/CONTACT US

Want to Discuss Your Upcoming Product Line?

Hinah coating will help you get things done.

Email us

Tel (Whatsapp/Wechat)

+86-186 3213 8668

Learn How We Helped 1000+ Customers Gain Success.